Summary

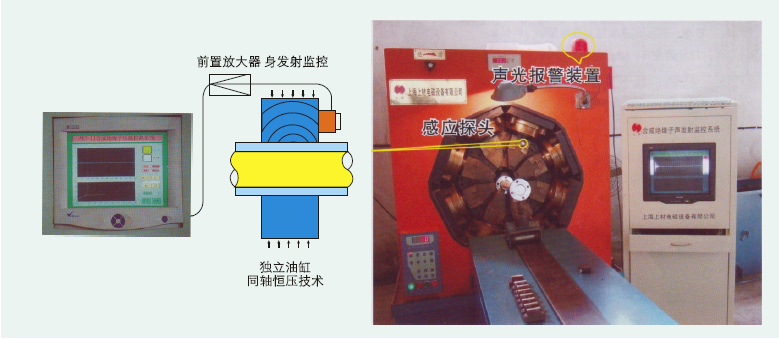

Composite rod insulator is composed of glass fiber epoxy rod polymer, silicone rubber sheath and two connecting fittings of three parts.

The epoxy glass fiber pull-out rod has high tensile strength, usually up to 600MPA, which is 2 times the ordinary steel, 2 times the ordinary steel and 5~8 times of the ceramic material. And has excellent insulating properties, chemical resistant performance, good anti bending, torsional strength, creep resistance and impact resistance, high silica umbrella have good hydrophobicity, stain resistant ability is very high and has good corrosion resistance, resistance to corrosion, chemical resistance, and the porcelain insulator phase than in flashover under the same conditions as the voltage is more than 2 times the porcelain.

The composite insulators manufactured by our company are made of special steel and iron fittings. While ensuring the strength of the fittings, the broken ends are labyrinth waterproof design, multi-layer seal and good sealing performance, which solves the most critical problem of insulators -- the breakdown of the interface electrical appliances. The connection between fittings and mandrel is based on the most advanced computer controlled coaxial constant voltage crimping technology in the world, and is equipped with a fully automatic sound emission and shooting flaw detection system, which ensures the reliability and stability of metal fittings and rod core crimping. The umbrella cover uses a disposable integral forming process under high temperature and high pressure, with two vulcanization computer monitoring, prolong the service life of the product. The cash production equipment and testing means ensure that all the technical indicators of the product meet the domestic and international standards, and become the new generation insulator of HV transmission and transformation lines.

Product characteristics

1. small size, light weight, the same voltage grade porcelain insulators about 1/5~1/9, resistance to collision, easy to transport and installation.

2. High mechanical strength, high lift load, reliable structure, stable performance and large safety operation margin.

3. composite insulator has excellent electrical performance, silicone rubber has good hydrophobicity and mobility, strong anti flashover capability, safe operation in heavy dirty area, and no artificial cleaning. It can avoid zero value maintenance.

4. The insulators are resistant to brittle properties of acid, alkali and heat-resistant aging, strong earthquake resistance and no brittle fracture.

5. According to the interchangeability of insulators, it can be used interchangeably with porcelain insulation.

Applicable conditions

1. environment temperature: -40 C -+40 C;

2. less than 1500 meters altitude;

3. the AC power frequency: 100HZ;

4. the maximum wind speed does not exceed: 35m/s;

5. Seismic intensity: below 7 degrees

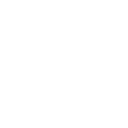

The key link of insulator manufacturing -- the technology of the joint pressure and monitoring of the metal fittings

The bonding technology of insulators directly determines the tensile strength of the insulation. Our company adopts 500 tons 8 cylinder computer control insulator then press the most advanced manufacturing technology, its use in the field of aerospace, hardware pressing process of acoustic emission monitoring technology, the sensitivity can be resolved several root glass fiber telomeres, and equipped with sound and light alarm device, ensure the pressure quality no danger of anything going wrong. The advanced 8 cylinder coaxial constant voltage technology has overcome the unstability of the breakfast bonding quality due to the diameter error of the fittings, and the uniformity of the 8 cylinder crimping ratio and the 6 cylinder press connection is better. It is the most advanced way of crimping in the world at present.

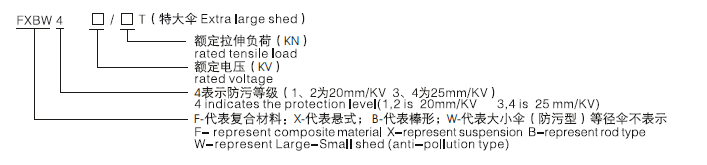

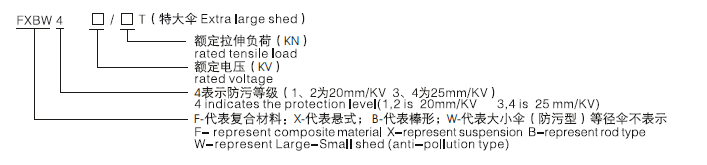

Product model description

|

Type

|

Rated voitage Kv

|

rated mechanical tensile load Kn

|

connecting structure sign

|

structure electric mm

|

minimum electric arc distance mm

|

minimu nominal creepage distance mm

|

lightning strike voltage(full wave)no less than<KV

|

power frequency 1min wet withstand voiltage noless than <KV

|

|

FXBW4-35/70

|

35

|

70

|

16

|

650±15

|

450

|

1015

|

230

|

95

|

|

FXBW4-35/100

|

35

|

100

|

16

|

650±15

|

450

|

1015

|

230

|

95

|

PREV:FXBW4-10 C type rod type suspension composite insulators

PREV:FXBW4-10 C type rod type suspension composite insulators

MOBILE

MOBILE WeChat

WeChat